The wavelength of fiber lasers is 0.06 microns. This difference is 10 times smaller than the wavelength of CO2 lasers. A fiber laser beam produces a wavelength of 1.06 microns, which is 10 percent smaller than that of a CO2 light source. However, a CO2 light source is much more likely be absorbed by reflective materials. Fiber laser cutting machines have the ability to cut brass, copper, or other reflective materials. Note that CO2 laser light that reflects off the material could not only damage the machine's optical system, but also the entire beam pathway. This risk is eliminated when the beam path is made of fiber-optic cable.

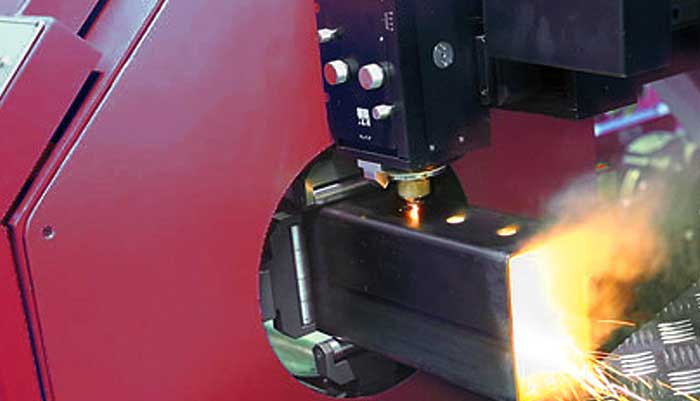

The Coherent StarCut Tube hybrid version offers the best flexibility to cut different medical devices in metals and plastics from flat stock or tubes. This compact, turnkey laser machine combines two lasers into one compact housing.